ERPNext’s powerful manufacturing capabilities make it suitable for any discrete or process manufacturing use case. ERPNext also supports complex engineer to order workflows.

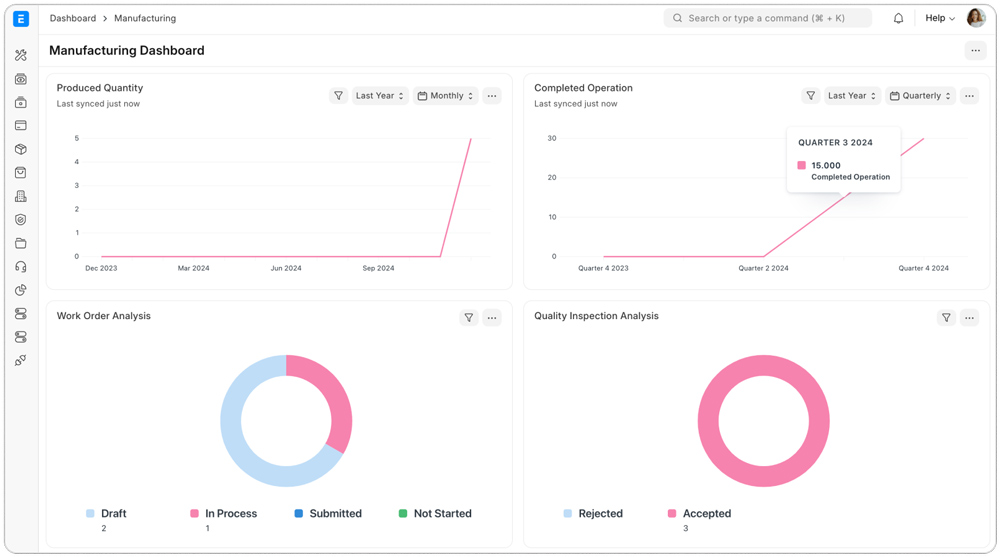

With ERPNext, all your business information is centralized in one place and seamlessly connected. Imagine a system where delivering to your customers automatically updates the corresponding Sales Order status, ensuring you always know what’s completed and what’s pending. A single connected system helps you make sense of your operations, even in a visual-way through Dashboards.

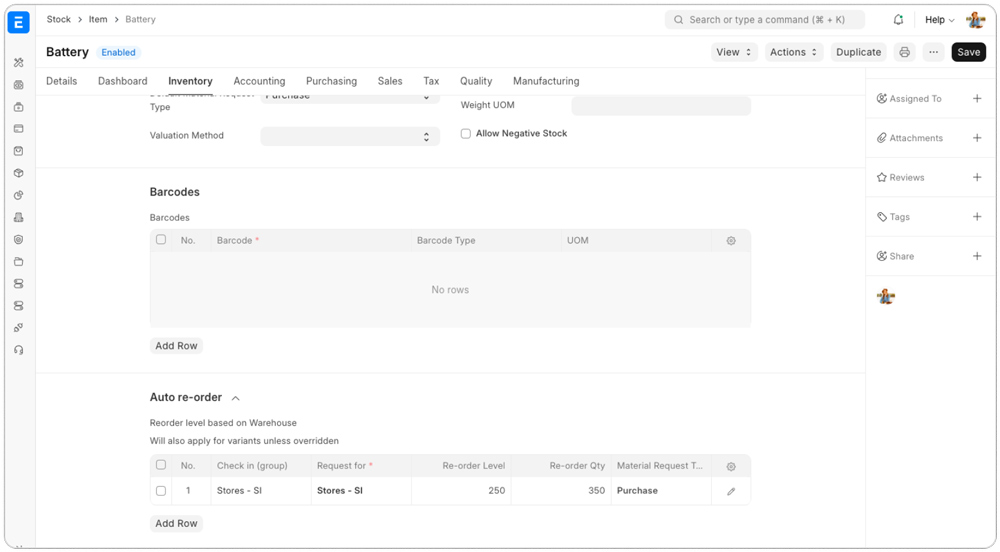

Take the guesswork out of your planning, plan based on what you need. ERPNext can help you plan your raw materials for Made to Order, Made to Stock or even Engineer to Order scenarios. ERPNext even keeps a tab on your Projected Quantity based on expected incoming and outgoing quantities. ERPNext’s easy-to-use Production Plan simplifies your Materials Requirement Planning process. It also creates a Material Request automatically so that you can focus on growing your business!

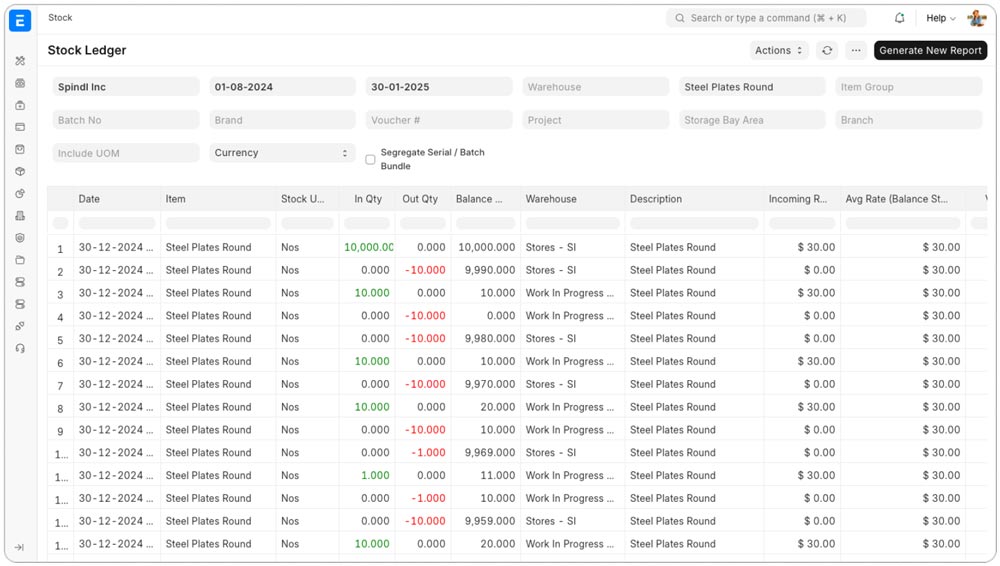

Get complete visibility of your inventory. ERPNext helps you record each inventory transaction with highly contextual information. You will know exactly why that piece of inventory left that warehouse. ERPNext offers all the traceability features along with an easy to use interface that helps you overcome all the excuses not to record that Serial Number or Batch Number.

Multi-Level Approval: Enable seamless collaboration with built-in accountability using easy-to-configure multi-level approval systems. Whether it’s your return merchandise authorization (R.M.A.) process or payment workflows, ensure every step is clear, controlled, and efficient

Automated Notifications: Avoid missing important events, set up automated notifications. ERPNext can even send automated payment follow-ups!

Quality control: Ensure your products meet industry regulations and quality standards without additional manual effort. ERPNext automates compliance documentation, quality control checks, and batch traceability, making ISO and other regulatory audits effortless.

Customer and supplier relations: Make smarter procurement decisions with real-time vendor and supplier performance analytics. Track key metrics such as on-time delivery rates and defect percentages to optimize your supply chain. Provide customers with a self-service portal for instant order tracking, reducing delays and improving satisfaction.

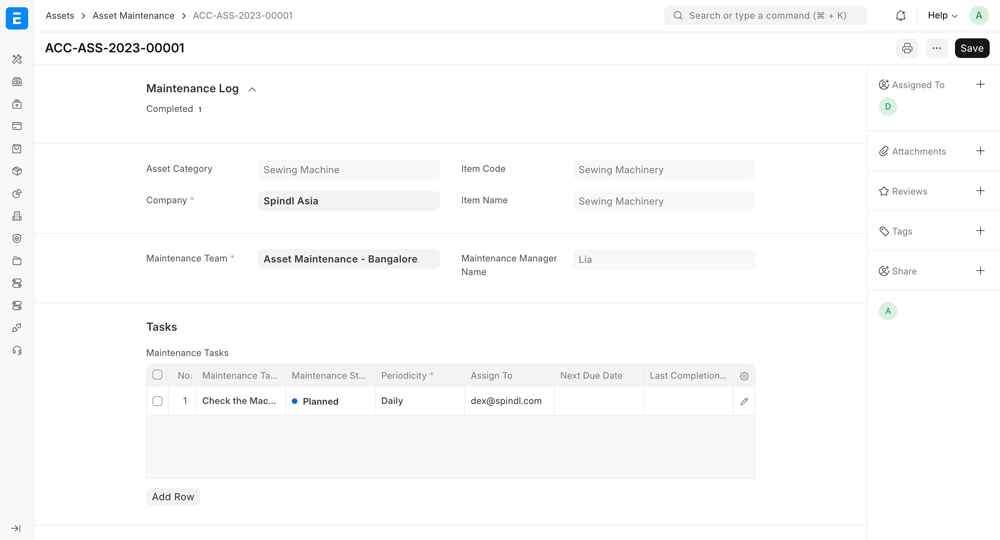

Production floor optimisation: Improve efficiency by tracking employee skills, assigning jobs intelligently, and reducing downtime. ERPNext’s integrated workforce management tools help allocate the right personnel for each task, enhancing overall productivity. IoT integration (not in-built) allows real-time shop floor updates, eliminating paperwork and streamlining operations.

Experience sustainable growth through innovative financial solutions, expert guidance, and personalized support tailored to you.

Empowering businesses with innovative, reliable, affordable solutions through cutting-edge technology and exceptional customer service.

Terms & Conditions

Privacy Policy

WhatsApp us